The main function of the Corrugated Roofing Sheet Roll Forming Machine is to produce curved roof tiles, suitable for buildings with corrugated roofs. This equipment can efficiently produce curved roof tiles with smooth appearance, uniform paint patterns, and high strength through roller forming and pressing technology. The corrugated roofing sheet roll machine adopts an automated control system and highly integrated network, which can achieve efficient production and ensure high product quality through sufficient exhaust and uniform mold pressure.

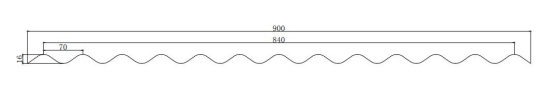

The profile drawing:

The pictures for the finished product:

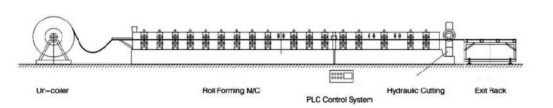

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Corrugated Roofing Sheet Roll Forming Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Corrugated Roofing Sheet Roll Forming Machine :

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel,Q235 |

| 2 | Raw material thickness | 0.18-0.28mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 20stations |

| 6 | Roller material | High grade 45# steel,chromed treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | High grade 45#,Tempering treatment |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 400mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated Roofing Sheet Roll Forming Machine :

1. Efficient production:

By adopting automated control systems and highly integrated networks, efficient production can be achieved.

2. High quality products:

The products produced have the characteristics of smooth and beautiful appearance, uniform paint patterns, high strength, and durability.

3. Multifunctionality:

By replacing different machine heads, different varieties and specifications of bricks and tiles can be produced to meet diverse production needs.

4. Economy:

It can reduce production labor, lower labor intensity, and thus lower production costs. The device is small in size, light in weight, easy to move and transport, and has good economy.

Machine photos: