The T-shaped keel machine is mainly used to produce T-shaped keels, which are widely used in ceiling decoration to provide stable support. The T-shaped keel machine improves production efficiency, reduces labor costs, and ensures the quality and consistency of the keel through fully automatic operation. The T-shaped keel produced by the T-shaped keel machine is suitable for various public places and civil buildings, such as hotels, terminals, passenger stations, shopping malls, factories, office buildings, etc. The T-shaped keel plays a role in supporting the ceiling in these places, ensuring the stability and aesthetics of the ceiling.

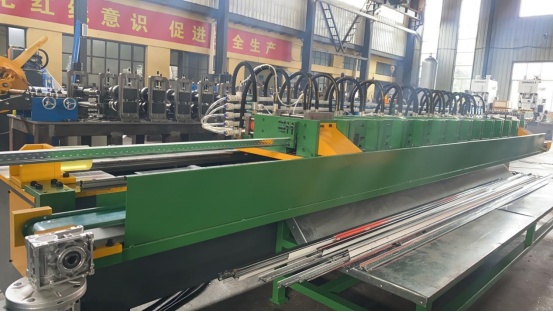

The pictures for the product:

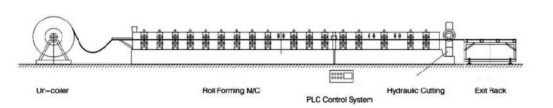

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the T-shaped keel machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the T-shaped keel machine :

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.6-1.2mm |

| 3 | Decoiler | 3T |

| 4 | Felt device | Available |

| 5 | Roller station | 10stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 50mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By gear |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | Vertical arch frame structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 3kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the T-shaped keel machine :

1. Improve production efficiency:

The T-shaped keel machine adopts a fully automatic operation interface, providing multiple language options and easy operation. Its energy storage rapid stamping technology enables punching and heading to be completed in one stamping, without the need to stop the machine for stamping, greatly improving production efficiency.

2. Quality assurance:

By adopting energy storage rapid stamping technology, the quality of each hole and head is ensured to be consistent, avoiding errors caused by manual operation and improving product consistency and stability.

3. Environmental protection and energy conservation:

Using Siemens all copper wire motor ensures smooth transmission, low noise, reduces energy waste, and meets the requirements of environmental protection and energy conservation.