Floor deck roll forming machine is a mechanical device specifically used for producing floor slabs. As an important building material, floor slabs are widely used in steel structure buildings, such as power plants, power equipment companies, car exhibition halls, steel structure factories, cement warehouses, steel structure offices, airport terminals, sports venues, and other places.

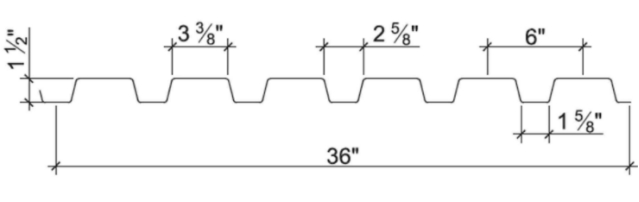

The profile drawing:

The pictures for the finished product:

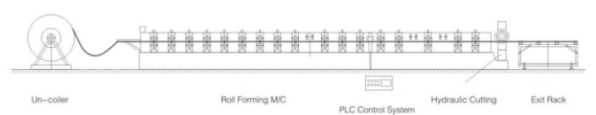

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving.

Production process:

Packing list of the floor deck roll forming machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the floor deck roll forming machine:

| Item | Name | Specifications |

| 1 | Raw material | GI&PPGI |

| 2 | Raw material thickness | 0.7-1.5mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 28stations |

| 6 | Roller material | 45# steel |

| 7 | Shaft diameter | 85mm |

| 8 | Shaft material | 45# steel |

| 9 | Transmission | By double chains |

| 10 | Motor power | 5.5kw |

| 11 | Machine frame | 400H steel |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Cr12 quenched |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the floor deck roll forming machine:

1. Efficient automation:

The floor deck roll forming machine usually adopts advanced automation production technology, which can efficiently complete the pressing and forming work of the floor support plate and improve production efficiency.

2. High precision:

During the production process, the floor deck roll forming machine ensures the dimensional and shape accuracy of the floor slab through precise control systems and forming processes, meeting the requirements of the building.

3. Strong adaptability:

The floor deck roll forming machine can adapt to the production needs of different specifications and models of floor support plates. By adjusting equipment parameters and molds, multiple types of floor support plates can be produced.

4. High material utilization rate:

During the production process, the floor floor deck roll forming machine can fully utilize raw materials, reduce material waste, and lower production costs.

Machine parts :

(1)Hydraulic Decoiler:

(2)The feeders:

(3)Cutting device:

(4)Products receiving: