Drywall roll forming machine, also known as a drywall studformer, is significant industrial equipment in the construction field. It’s mainly used to make metal framing components for drywall systems like studs, tracks and other structural parts that build the framework of walls and ceilings. These components are crucial for the stability and integrity of buildings.

The process starts with flat metal sheets typically made of galvanized steel due to its good corrosion resistance. A series of rollers in the machine work together to gradually roll these sheets into specific profiles. Each roller plays a role in precisely shaping the metal, ensuring the final components meet the requirements for drywall installations in different construction projects.

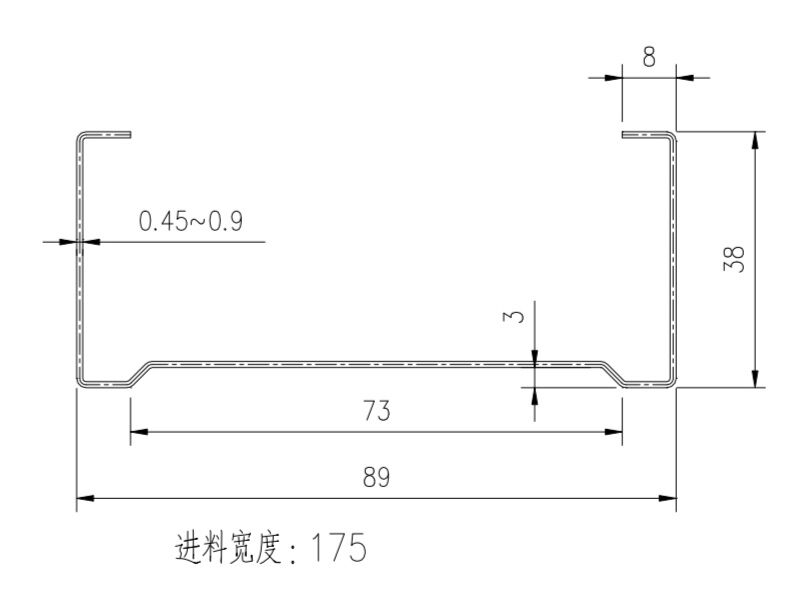

Customer drawing profile:

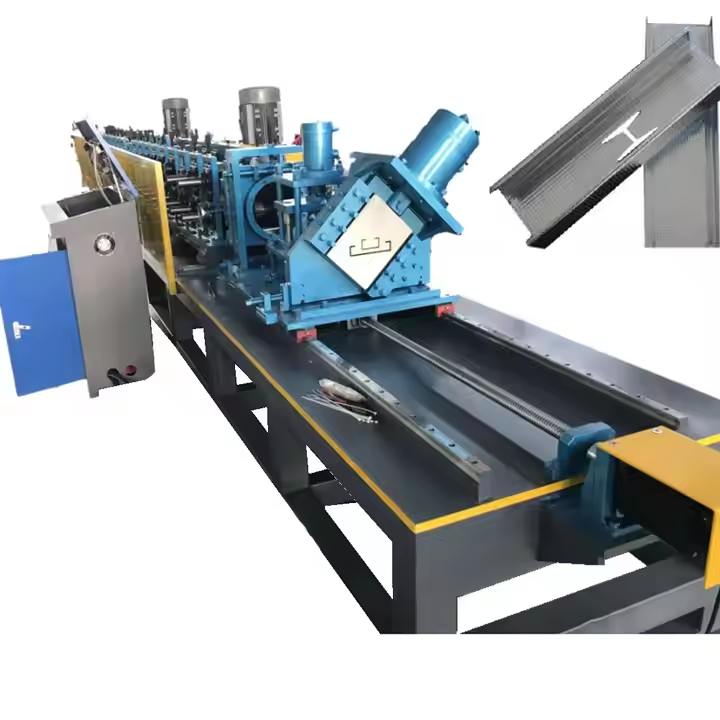

Drywall roll forming machine:

Technical of machine

1.3tons hydraulic decoiler

| Roller station | 12 rows(As your requirement) |

| Diameter of shaft | 50mm solid shaft |

| Material of rollers | Cr12, hard chrome plated on the surface |

| Machine body frame | 400 H steel |

| Drive | Gear transmission |

| Dimension(L*W*H) | 12000*1800*1600(customize) |

| Motor power | 7.5KW |

| Hydraulic power | 5.5kw |

| Working voltage | 220V-60HZ-3Phase |

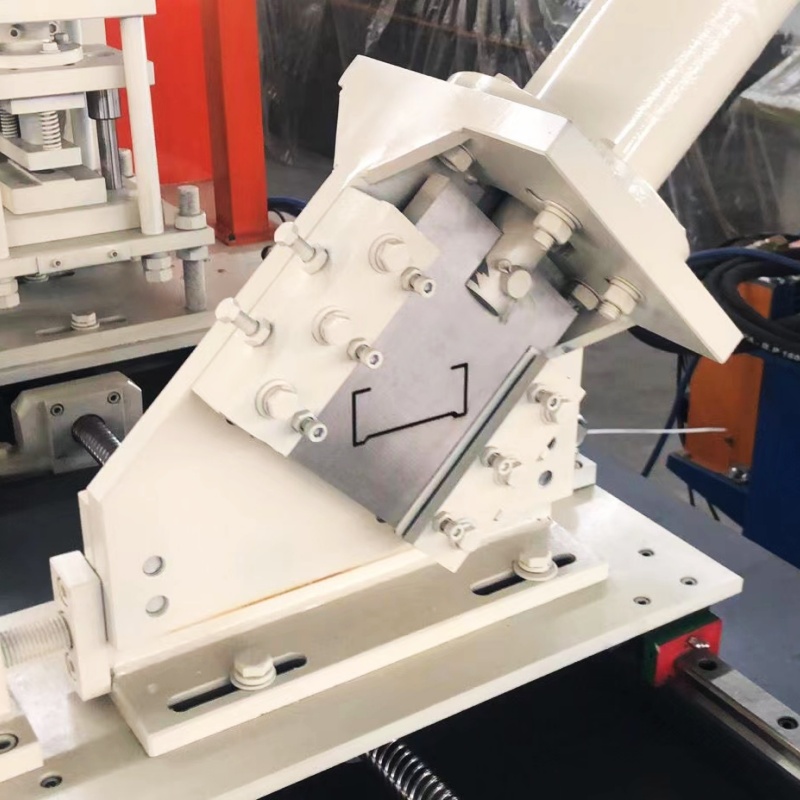

Some detailed photos of the machine

Recommend related machine:

Cangzhou Zhongtuo has decades of experience in the manufacturing of cold roll forming equipment. If you are in need of cold roll forming equipment, you can feel free to consult us at any time.