The U profile roll forming machine is a highly efficient piece of equipment. It plays a crucial role in the manufacturing industry. With its advanced technology, the U roll forming machine can transform raw materials into precisely formed U studs. We rely on this machine to ensure high-quality production. Moreover, the machine is easy to operate. It allows for seamless production processes. As we continue to expand our operations, we will undoubtedly need more U profile roll forming machines. These machines will help us meet the growing demand for U studs and contribute to the success of our business.

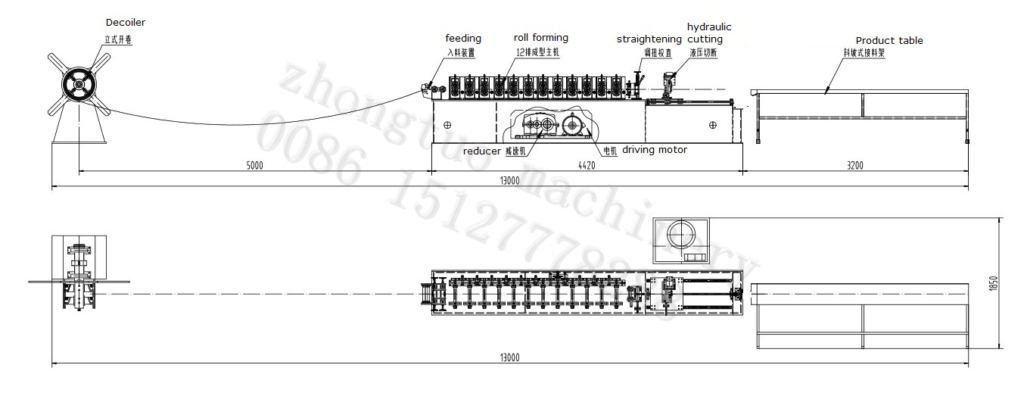

The work flow for U profile roll forming machine:

Main parameters of machine:

| Loading capacity | 3 Tons |

| Coil inner diameter | 450-550 mm (adjustable) |

| Coil outer diameter | 1500 mm |

| Coil width | 350 mm |

| Straighten device | Double hand wheels |

| Rolling shaft | Shaft material: 45# steel |

| Shaft diameter: 40 mm | |

| Tempering treatment | |

| Roller | Roller material: Cr12 |

| Quenched treatment | |

| Rolling station number | 10 stations include the rolling stations for rib and knurling |

| Work speed | 0-20 m/min |

| Machine frame | Vertical arch frame structure |

| Machine body | steel plate welded with grinding |

| Work power | 4 kw |

| Transmission | By Gear |

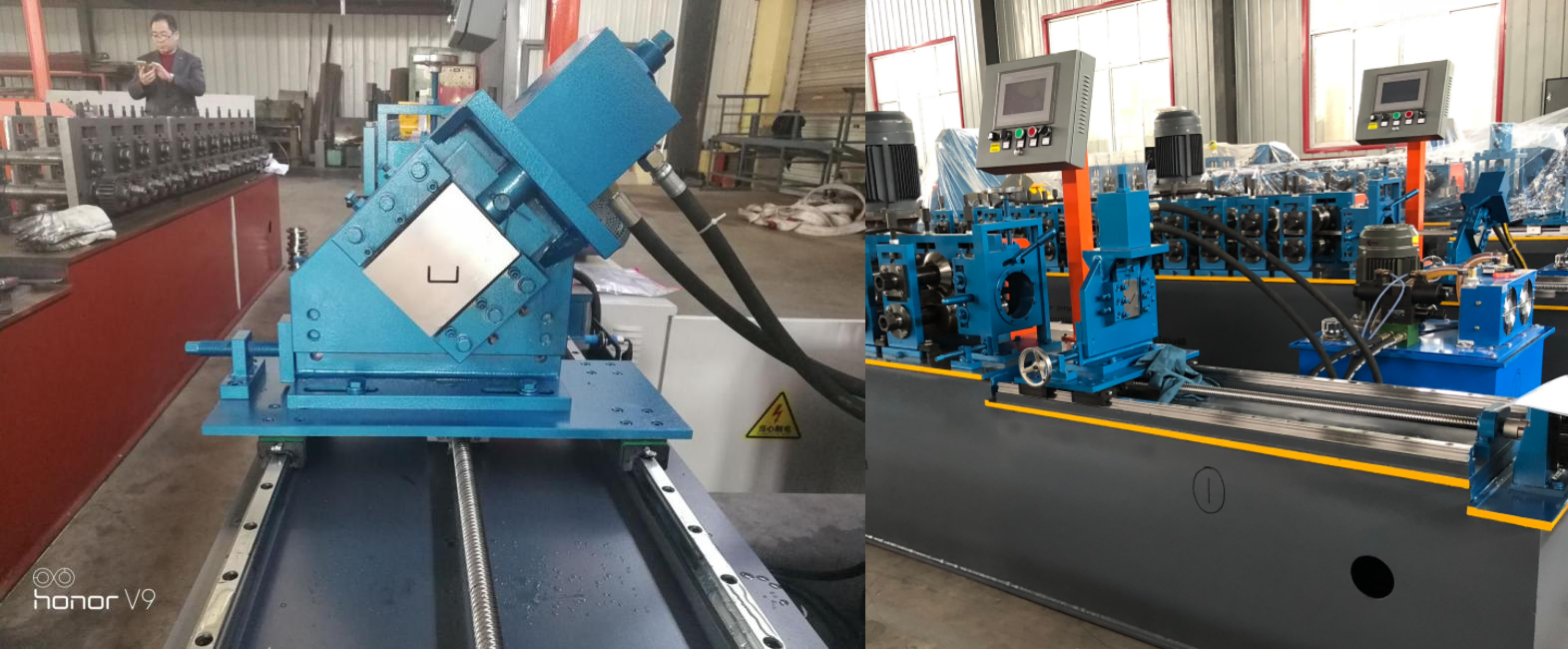

PLC control system and cutting system

Other pictures of the machine:

Recommend related machine: