How to choose thin-walled light steel equipment?

A set of good quality cold-curved thin-walled light steel processing equipment should have the following characteristics:

1. The device should be able to identify the design software data and seamlessly dock: automatically read the data output from the design software.

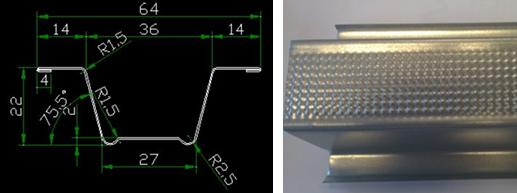

2. Equipment processing rod components in line with industry standards Reference JGJ 227-2011,GB50018,JGJ/T 421-2018, the function to meet the light steel building connection node. 3. High precision of equipment processing, need to customize the special PLC according to the function of light steel equipment, accurate calculation, fast response speed.

In the on-line production of post-punching shear equipment, two errors of hole displacement caused by tensile and extrusion of raw materials can be avoided during the compression process. About the equipment control system, the use of PLC+ Motion controller control technology has lagged behind, the industry’s top equipment are using a new generation of PC-based Fieldbus control system, its stability, accuracy, response speed, easy maintenance and other aspects of the PLC control platform.

The equipment of the FRAMECAD in New Zealand has all been upgraded to this high-performance control system.

4. High yield of equipment, less waste: the length of the rear punching and shearing equipment detection mechanism and punching shear mold distance, so the boot head scrap can be controlled in 0.02m-0.05m, material tail scrap does not exceed 1m.

5. Front punching shear equipment, length detection mechanism away from the shear mold distance, so the boot head scrap is greater than 2m, the length of the material tail scrap is larger than the length of the equipment generally more than 5m. There are light steel houses on-site assembly experience of experts, will be in addition to the number of design requirements, the production of a few additional long-pole parts, in the construction site according to the need to cut to the appropriate length, to do temporary support and connection. The end of the material head material produced by the “front punching and cutting” device is just for this purpose.

There is no waste. 6. Equipment processing efficiency is high, the comprehensive processing speed is generally not less than 4 tons/day (8 hours) ≈160m²/days. The wall processing speed is not less than 600m/h.

High-speed cold bending thin-walled light steel processing equipment comprehensive processing capacity of 6-10 tons/day (8 hours).

7. Equipment needs to be equipped with spray code device: can automatically spray code, instead of manual handwriting number. 8. In the process of equipment processing should be as far as possible to avoid scratches on the surface of the material, high-speed equipment should be equipped with roll and raw material cooling lubrication system, pressure processing before the surface of the raw material spraying or rolling cooling protection solution to reduce the scratches of the pressure process.

Side taper roll lining bearing as a driven roll effect is better. Production is stable.

As for rolling lubrication cooling protection solution, can not use as much as possible, the material surface has oil, inkjet machine hit the code, a wipe off. 9. Continuous flushing plate hole does not squeeze material, low failure rate: the front punching shear equipment in the online production of raw materials first resection of the web and roll edge, the strength is greatly reduced, in the pressure has a large rolling force and resistance is very easy to cause extrusion, especially in the case of continuous resection of the webs and coils.

This phenomenon can be completely avoided by removing the webs and coils after the compression of the rear punching shear equipment.

10. The addition of stiffeners to the ventral plate will increase the bearing capacity of the keel by about 28% of the strength, the market also has the abdominal plate plus stiffeners of the equipment, but the punching water pipe hole cut off the reinforcement, strengthen the tendon to lose the role of strengthening, and cause stress concentration. 11. Vertical keel support to the bottom of the Tiandi keel, the weight of the house is directly carried by the vertical keel, the house is safer.

Ordinary connection vertical keel at both ends did not support to the bottom of the Tiandi keel, the weight of the house depends on the friction of the nail nest, the tension of the connecting screws and shear force joint bearing.

The cold-formed thin-walled light steel frame building System (guagesteel), a relatively traditional beam-column structure, is characterized by vertical bearing of the whole building (such as static load, dynamic load in the house), lateral shear force (such as transverse wind, Earthquakes) and other external forces through the connection of the frame, the decomposition of it into each rod in the frame or even skin, so that each unit is involved in the commitment force. An imprecise analogy: under the premise of the same amount of steel, the LGS structure is 2 tall (vertical keel), 3 dwarves (oblique support), 1 girls (skin) carrying heavy loads together, can carry the 1000 KGS;

The traditional beam and column structure only 2 tall (vertical keel, transverse keel) carrying heavy loads, the other 4 people do not have the force, naturally can only carry 700KGS. In the mechanical system of the frame structure, if the vertical keel is directly supported to the bottom of the transverse keel webs, the load of the building is passed directly to the vertical keel through the transverse keel, and becomes the force of the beam and column structure, which is equal to the vertical keel of the C89 size as a “pillar”, a row of fine columns.

This is not a cold-bent thin-walled light steel frame structure. The dimple hole (dimple hole) screw connection is a great invention in the light steel frame structure, it is through the tight friction between the concave and convex surface of the nest nail hole that the various forces of the House can be decomposed into different rod directions, so that the overall load is shared by all the units in the frame.

That’s why there’s always a gap in the connection of the vertical keel in FRAMECAD’s design.

The vertical keel cannot top the bottom of the ventral plate of the transverse keel, which is common sense of the light steel frame structure. 12. High-temperature areas can be produced for a long time, cold bending thin-walled light steel processing equipment online production of the time in punching and shearing, hydraulic system long time high pressure and high frequency of the work of hydraulic oil temperature is easy to be too high, so must be equipped with refrigeration system or water cooling system, some equipment configured air cooling system, If the ambient temperature is higher than 40 degrees, the cooling requirements of the hydraulic system can not be met at all.

Production and processing stability, low failure rate, to give users to ensure that on time according to the amount of processing orders.

To ensure long-term stability at work, oil temperature normal, technical attention to a few points:

1) The fuel tank of the hydraulic station should be large enough.

2) hydraulic system used in hydraulic valves, cylinders, accumulators and other components are best international brands, such as the German national power, Parker, USA and so on. 3) Under the premise of meeting the requirements of punching and cutting work, the lower the pressure of the hydraulic system when working, the better.

This is a good understanding, “high blood pressure died fast.” 4) High-end equipment will generally choose the international brand piston pump, and the rest will only use gear pump. Oil pumps are important, there is a 3 times-fold gap in prices, and work performance is very different from durability.