Snap lock standing seam is created by “snapping” on side of a metal roofing panel onto another so that they hook together and are fastened to the roof by a nailing flange then hidden by the next sheet, no special tools needed for installation. As the demand of the market, we have developed the Snap-Lock Standing Seam roofing sheet rolling forming machine.

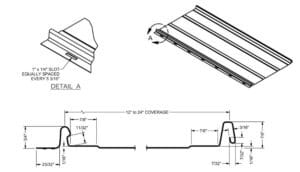

Take the following Snap-Lock Standing Seam roofing sheet drawing profile for examples:

Popular design 1:

Popular design 2:

Snap-Lock Standing Seam roofing sheet rolling forming machine design:

| Product sheet | Raw material | GI&PPGI&G550 | ||

| Material thickness | 0.3-0.8 mm | |||

| Feeding width | 1220mm | |||

| Effective width | 930 mm | |||

| Sheet cutting length | Adjustable | |||

| Main roll former | ||||

|

Roll forming machine |

Feeding device |

One set guiding roller | ||

| Steel plate welded platform to carry the sheet and feed into roll forming system | ||||

| Feeding width is adjustable with the handle wheels. | ||||

|

Rolling shaft Roller |

Shaft material:45# STEEL | |||

| Shaft diameter: 75 mm | ||||

| Tempering treatment to prevent deformed and improve hardness. | ||||

| 45# steel 45 # сталь | ||||

| Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||||

| Rolling station | 20 rolling stations | |||

| Work speed | 20 m/min | |||

| Machine structure | Steel plate welded structure | |||

| Machine basic frame | 350# H steel welded | |||

| Work power | 7.5 kw | |||

| Rolling spacer | Anti rusty treatment | |||

| Pull rod | Anti rusty treatment | |||

| Transmission | By Chains with cover | |||

| Noted: please fill the lube in case the chains getting dry. | ||||

More details of the Snap-Lock Standing Seam roofing sheet rolling forming machine:

- High quality leveling beach with rollers for protecting the surface of the coil.

- The side roller design:

Snap-Lock Standing Seam roofing sheet Usage in daily life:

Snap-Lock Standing Seam roofing sheet rolling forming machine working videos for your reference: