Cable tray rolling forming machine is designed to make cable trays in batch fully automatically.Cable Tray System is used to support insulated cables or wiring for power control, communication and distribution.

In the commercial and industrial construction, cable tray is widely used as an alternative to open wiring or cables conduit system. And they are very useful in situation where changes to a cable system are expected. Because new cables can be installed by laying them in the tray, instead of pulling them through a pipe.Here are some cable tray pictures for your reference:

Types Of Cable Tray in the market.

Solid bottom cable tray

Ventilated cable tray

Ladder Tray

Cable tray cover

Channel cable tray

Nowadays, A Cable Tray Roll Former can produce both solid and ventilated cable trays, and also the cable tray cover.As to the cable which material is based on where it will be used, Galvanized tray may be made of pre-galvanized steel sheet fabricated into tray. Or may be hot-dip galvanized after fabrication. When galvanized tray is cut to length in the field. And usually the cut surface will be painted with a zinc-rich compound to protect the metal from corrosion. Based on the different types material, the machine of cable tray also will be different.

Zhongtuo Cable Tray Roll Forming Machine has some basic specification and parameters.

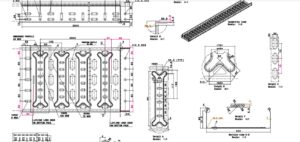

For showing the parameters, I will take this drawing profile for example to explain how the machine is composed:

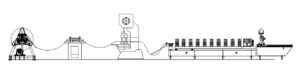

The whole line is consist of Uncoiler, Leveler, Servo Feeder and Punch Press, Roll Former, Cutoff Unit, Controlled Box, Collection Table.

Working flow of cable tray rolling forming machine:

Electric Uncoiling– leveling– Servo Feeding and Punching– Guiding–Roll Forming– Straightening– Tracking Cutting– Collecting.

ZHONGTUO Cable Tray Roll Forming Machine Main Elements

As to the decoiler, you can choose either hydraulic decoiler or the manual decoiler. As to the leveling part, we will design as Leveling roller: Upper 3,underneath 4 (totally 7 rollers), wit the Servo Feeder and Punch Press, Feeding type: Servo feeding, width of the material: 0-200mm

ZHONGTUO Cable Tray Machine ROLL FORMING MACHINE:

1.Forming Thickness: 1.0-2.5mm

2.Roll Forming Speed: 10-15m/min

3.Machine base adopt H Steel, welded, adopt iron cast pillar as the machine stands

4.Rollers Material: GCR15, quenched and tempered

5.Shaft Material: ASTM 1045, tempered, 75mm diameter

6.Motor Power of cable tray roll former : 15KW

7.Cable Tray Roll Forming Stands: 22 stands

8.Width Adjustment: PLC controlled automatically adjustment.

9.Drive type: By Chain or Gear Box+

Zhongtuo Cable tray rolling forming machine shearing part:

1.Before cutting for increasing the machine working speed.

2.Cutting Blade Material: Cr12Mov, Quench treatment, HRC58-62

3.Hydraulic Station Power: 15KW

Zhongtuo Cable tray rolling forming machine PLC Control System

1.Adopts PLC control technology, frequency adjust speed technology, realize the automatic production.

2.The worker can set the batches, length, quantity on the touch screen, then the cable tray roll forming machine will work automatically.

3.Operation type: Touching screen and Button

4.Using encoder to calculate the number and measuring the length

5.Electrical control: PLC frequency control system with touch screen

6.PLC: Panasonic Brand or Siemens

7.Encoder: Omron Brand

8.Touch Screen: MCGS or Siemens

9.Inverter: Yaskawa

10.Adopt aviation plug for easy connect the wiring