Normally speaking, the round wave roofing sheets are made by the metal rolling forming machines. But for South African and some area, they would like to use some thin sheet like the thickness from 0.13 to 0.2mm to make the metal roofing sheets. Limited by the rolling forming machine characters, it cannot be made by rolling forming machine, as it will be torn into pieces.Roof panel machine

Based on this need, barrel corrugated sheet rolling machine is developed based on the needs that thin sheet cannot be made to roof sheet by traditional roll forming machine. It can process material thickness from 0.15 to 0.30 mm and the roofing sheet length could be customized according to customer’s personal requirement. But limited by roll forming method, this machine needs to feed sheet and receive sheet by manual. ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

Using this type horizontal round wave making machine, first you need to cut the long coil into pieces, which the length is specified what you need. And then feeding coil to machine by pieces.

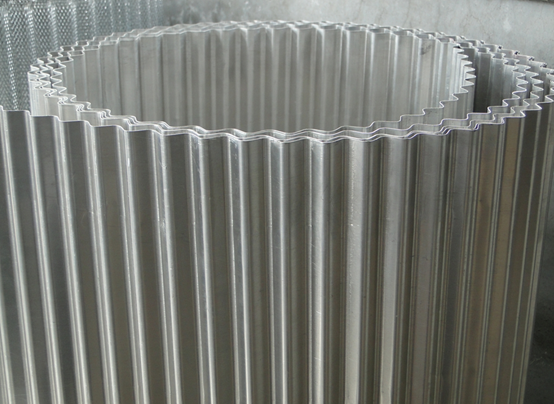

Here is the machine picture for your reference:

- Forming device

- .Roller station:2 sets

- .Roller diameter:300mm,Material:45# steel

- .Speed :15piece/min

- .Weight:8.5T

- .Voltage:380v,50hz,3ph

- . Motor: 11kw

And for checking how this machine works, please refer to the following video.

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/HQOUVdfpKbo” frameborder=”0″ allow=”accelerometer; autoplay; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>